copper thin film for rfid uhf antenna on flexible substrate A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was . NFC21 Tools allows you to write NFC tags conveniently on your Windows PC. The software is available from Windows 7 on and requires a corresponding NFC reader/writer, which is available in our shop: NFC-Reader. .

0 · Printing of passive RFID tag antennas on flexible substrates for

1 · Fabrication of a Flexible RFID Antenna by Using the Novel

2 · Copper thin film for RFID UHF antenna on flexible substrate

3 · Copper thin film for RFID UHF antenna on flexible

4 · Average thickness and resistivity of copper thin films at 40 W for

5 · Antioxidant high

$38.99

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was .A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen

It was found that the resistivity of the thin film is below two times the bulk resistivity of copper for a deposition pressure below 4 × 10−3 mbar and . The universal applications of as-prepared copper paste in flexible printed electronics (e.g., electromagnetic interference (EMI) shielding films, anti-fog films, and RFID .This paper aims to fill this gap; it focuses on printing UHF tag antennas on flexible substrates and relates the antenna performance with the printed layer properties. It considers two laboratory .Made available by U.S. Department of Energy Office of Scientific and Technical Information .

The techniques used to fabricate RFID antennas for UHF band applications are contrasted in Figure 8 and Table 2. We compare a novel additive procedure that utilizes the . A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was .Copper thin film for RFID UHF antenna on flexible substrate. Article. Full-text available. Aug 2010. Nhan Ai Tran. Huy Nam Tran. Chien Mau Dang. Eric Fribourg-Blanc. A process.

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its flexibility at laboratory scale.A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosenIt was found that the resistivity of the thin film is below two times the bulk resistivity of copper for a deposition pressure below 4 × 10−3 mbar and thickness above 450 nm. These results enable the reliable fabrication of copper RFID UHF antennae on .

Printing of passive RFID tag antennas on flexible substrates for

The universal applications of as-prepared copper paste in flexible printed electronics (e.g., electromagnetic interference (EMI) shielding films, anti-fog films, and RFID tags) via screen.This paper aims to fill this gap; it focuses on printing UHF tag antennas on flexible substrates and relates the antenna performance with the printed layer properties. It considers two laboratory-scale additive printing techniques most used in research: inkjet printing and screen printing.

Made available by U.S. Department of Energy Office of Scientific and Technical Information .

The techniques used to fabricate RFID antennas for UHF band applications are contrasted in Figure 8 and Table 2. We compare a novel additive procedure that utilizes the galvanic displacement reaction of PET film to the conventional subtractive method, which involves etching copper foil.

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its.

Copper thin film for RFID UHF antenna on flexible substrate. Article. Full-text available. Aug 2010. Nhan Ai Tran. Huy Nam Tran. Chien Mau Dang. Eric Fribourg-Blanc. A process.Copper thin film for RFID UHF antenna on flexible substrate 🔍 IOP Publishing; Institute of Physics Publishing (IOP) (ISSN 2043-6254), Advances in Natural Sciences: Nanoscience and Nanotechnology, #2, 1, pages 025016-, 2010 jun 01 A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its flexibility at laboratory scale.

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosenIt was found that the resistivity of the thin film is below two times the bulk resistivity of copper for a deposition pressure below 4 × 10−3 mbar and thickness above 450 nm. These results enable the reliable fabrication of copper RFID UHF antennae on . The universal applications of as-prepared copper paste in flexible printed electronics (e.g., electromagnetic interference (EMI) shielding films, anti-fog films, and RFID tags) via screen.

This paper aims to fill this gap; it focuses on printing UHF tag antennas on flexible substrates and relates the antenna performance with the printed layer properties. It considers two laboratory-scale additive printing techniques most used in research: inkjet printing and screen printing.Made available by U.S. Department of Energy Office of Scientific and Technical Information . The techniques used to fabricate RFID antennas for UHF band applications are contrasted in Figure 8 and Table 2. We compare a novel additive procedure that utilizes the galvanic displacement reaction of PET film to the conventional subtractive method, which involves etching copper foil.

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its.Copper thin film for RFID UHF antenna on flexible substrate. Article. Full-text available. Aug 2010. Nhan Ai Tran. Huy Nam Tran. Chien Mau Dang. Eric Fribourg-Blanc. A process.

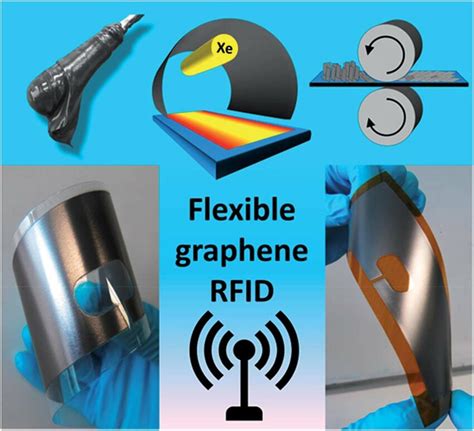

Fabrication of a Flexible RFID Antenna by Using the Novel

rfid chip in forhead

rfid chip industrie

rfid chip implant in india

Copper thin film for RFID UHF antenna on flexible substrate

Here’s how you can read NFC tags with your iPhone: Activate NFC Reader Mode: Ensure that your iPhone is in NFC reader mode, allowing it to detect and interact with nearby .

copper thin film for rfid uhf antenna on flexible substrate|Antioxidant high