rfid for manufacturing waste management and tracking We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly.

Head to the system screen on the far right, then hit options. The first option here will allow you to turn on amiibo. Now we're ready to go. An amiibo option will now appear as a rune in the game .They are meant to be printed at 300 dpi with dimensions 7.2cm width and 9.7cm .

0 · waste management rfid tags

1 · rfid tags for manufacturing

2 · rfid manufacturing technology

3 · rfid labels in manufacturing

4 · rfid for waste management

5 · field proven rfid tags

6 · cybra rfid

The 32-team National Football League is divided into two conferences, the American Football Conference (AFC) and the National Football Conference (NFC). Since 2002, each conference has 16 teams and is further divided into four geographic divisions of four teams each. As of 2020, qualification into the playoffs works as follows: • The four division champions from each conference (the team in each division with the best ove.

Discover how RFID and other tracking technologies can significantly enhance sustainability efforts. By providing precise, real-time data on assets and inventory, these .Get field-proven tags and reader boards for waste management tracking from the RFID tag leader. HID helps municipalities and waste removal services to improve waste collection .

Discover how RFID and other tracking technologies can significantly enhance sustainability efforts. By providing precise, real-time data on assets and inventory, these technologies empower businesses to optimize resource use, minimize waste, and streamline supply chains. . Work in progress tracking Track manufacturing processes to optimise .Get field-proven tags and reader boards for waste management tracking from the RFID tag leader. HID helps municipalities and waste removal services to improve waste collection automation and optimize waste management fleet tracking to enable pay-as-you-throw and recycling incentive programs.

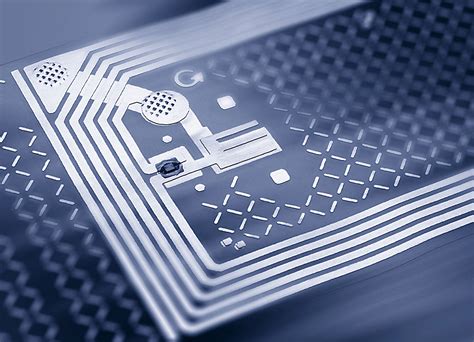

In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle. We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly. Manufacturing Flow Management: RFID technology helps streamline assembly lines. Streamlined automation in the assembly line reduces throughput time. RFID-enabled automation and tracking also improves the visibility of products and their velocity in the supply chain (Arjun et al., 2021; Kapoor et al., 2021). Returns ManagementDiscover Waste Management RFID Tags for efficient tracking and monitoring. Learn about real-life applications and case studies in the U.S. and Canada.

The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work?

RFID tags can be used to track inventory, automate processes, and improve supply chain management. With RFID technology, manufacturers can reduce cycle count time, minimize manual tasks, and eliminate the “search regret” effect.

Enhance RFID in Manufacturing with RFID asset tracking, work-in-progress monitoring, and inventory management. Use RFID tags and readers to streamline operations. RFID and other tracking technologies can provide you with real-time, accurate data to help you improve your workflows and save time spent carrying out manual recording and stock checks. Here are five ways in which data from tracking technologies helps improve performance: 1. . Discover how RFID and other tracking technologies can significantly enhance sustainability efforts. By providing precise, real-time data on assets and inventory, these technologies empower businesses to optimize resource use, minimize waste, and streamline supply chains. . Work in progress tracking Track manufacturing processes to optimise .Get field-proven tags and reader boards for waste management tracking from the RFID tag leader. HID helps municipalities and waste removal services to improve waste collection automation and optimize waste management fleet tracking to enable pay-as-you-throw and recycling incentive programs.

In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle. We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly. Manufacturing Flow Management: RFID technology helps streamline assembly lines. Streamlined automation in the assembly line reduces throughput time. RFID-enabled automation and tracking also improves the visibility of products and their velocity in the supply chain (Arjun et al., 2021; Kapoor et al., 2021). Returns ManagementDiscover Waste Management RFID Tags for efficient tracking and monitoring. Learn about real-life applications and case studies in the U.S. and Canada.

The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work?RFID tags can be used to track inventory, automate processes, and improve supply chain management. With RFID technology, manufacturers can reduce cycle count time, minimize manual tasks, and eliminate the “search regret” effect.Enhance RFID in Manufacturing with RFID asset tracking, work-in-progress monitoring, and inventory management. Use RFID tags and readers to streamline operations.

waste management rfid tags

rfid tags for manufacturing

rfid manufacturing technology

rfid labels in manufacturing

rfid for waste management

This new NFC enabled physical card allows you to spend BTC via the Lightning Network as well as GBP and EUR directly from your CoinCorner account. . The Bolt Card is the world’s first contactless Bitcoin Lightning card, a new way to .YARONGTECH NFC Blank PVC Card Details: -10pcs Glossy finish laminated white PVC cards-Brand YARONGTECH, Printable (with .

rfid for manufacturing waste management and tracking|rfid tags for manufacturing