1 what is the role of rfid chips in logistics RFID in supply chain involves using tags, hardware, and software. A complete solution has individual parts, products, or containers receive tags, and then both automated and hand RFID readers relay vital data to the management software.

Samsung Pay will be supported on the Gear S3 after being trialled on the Gear S2. Using NFC and MST (magnetic secure transmission), you’ll be able to tap your watch against any card reader.

0 · where are rfid chips used

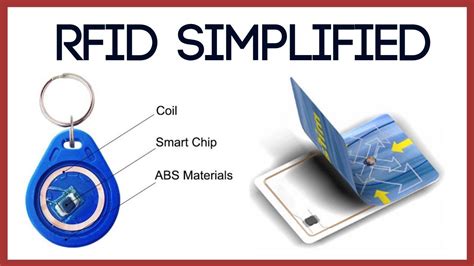

1 · what makes something rfid

2 · what does rfid look like

3 · types of rfid chips

4 · rfid is involved when using

5 · rfid for personal use

6 · how does rfid scanning work

7 · how do rfid chips work

Softonic review. NFC Reader - A Must-Have Tool to Scan NFC Tags. NFC Reader is a free application allowing you to scan any tag, in order to copy its contents to your device. This tool lets you read all NFC tags and .

RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. Here are some of the benefits RFID can bring to the supply chain. .Unlock the potential of RFID technology in logistics and supply chain management! Discover how RFID enhances efficiency, reduces costs, and improves traceability. Explore real-world . RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. Here are some of the benefits RFID can bring to the supply chain. 1. Improves product tracking through WMS integration.Unlock the potential of RFID technology in logistics and supply chain management! Discover how RFID enhances efficiency, reduces costs, and improves traceability. Explore real-world applications, industry benefits, and essential implementation steps for your business.

RFID technology has a variety of benefits for supply chain management. 1. Improved Inventory Management and Accuracy. An RFID system enables real-time inventory tracking, so companies can quickly and accurately locate items in their warehouses or throughout the supply chain journey.

RFID in supply chain involves using tags, hardware, and software. A complete solution has individual parts, products, or containers receive tags, and then both automated and hand RFID readers relay vital data to the management software.By tracking and managing goods in real-time, RFID can effectively improve logistics efficiency, reduce errors and reduce costs. This article will provide a comprehensive guide for beginners, detailing the application, implementation steps, and advantages of RFID in logistics, as well as helping users better understand and utilize RFID . Supply-chain management and logistics provide the greatest opportunity for applications of RFID technologies. These functions need technology to process large volumes of goods at high speeds. RFID in the supply chain brings efficiency at every touch point. Radio-frequency identification (RFID) technology is helping companies within the industry to do just that. By providing fast and accurate identification of items throughout a company’s supply chain, RFID reduces errors and delays, thereby improving overall efficiency in supply chain management.

RFID streamlines reverse logistics by: Enabling real-time tracking of returned products, simplifying the identification of defects. Automating data collection on returned items, reducing manual intervention. Enhancing the accuracy of tracking returned goods, which is critical for refurbishing or recycling. Example: BMW’s Use of RFID in . We’ll see how it can really help your business. Table of Contents. Key Takeaways. RFID integration with WMS significantly boosts product tracking and inventory counting speed, ensuring more accurate warehouse operations. RFID technology is emerging as a game changer in logistics and supply chain management. The post elaborates on every aspect of incorporating it in your business. RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. Here are some of the benefits RFID can bring to the supply chain. 1. Improves product tracking through WMS integration.

product eccn number rfid badge

Unlock the potential of RFID technology in logistics and supply chain management! Discover how RFID enhances efficiency, reduces costs, and improves traceability. Explore real-world applications, industry benefits, and essential implementation steps for your business. RFID technology has a variety of benefits for supply chain management. 1. Improved Inventory Management and Accuracy. An RFID system enables real-time inventory tracking, so companies can quickly and accurately locate items in their warehouses or throughout the supply chain journey. RFID in supply chain involves using tags, hardware, and software. A complete solution has individual parts, products, or containers receive tags, and then both automated and hand RFID readers relay vital data to the management software.

By tracking and managing goods in real-time, RFID can effectively improve logistics efficiency, reduce errors and reduce costs. This article will provide a comprehensive guide for beginners, detailing the application, implementation steps, and advantages of RFID in logistics, as well as helping users better understand and utilize RFID . Supply-chain management and logistics provide the greatest opportunity for applications of RFID technologies. These functions need technology to process large volumes of goods at high speeds. RFID in the supply chain brings efficiency at every touch point. Radio-frequency identification (RFID) technology is helping companies within the industry to do just that. By providing fast and accurate identification of items throughout a company’s supply chain, RFID reduces errors and delays, thereby improving overall efficiency in supply chain management.

RFID streamlines reverse logistics by: Enabling real-time tracking of returned products, simplifying the identification of defects. Automating data collection on returned items, reducing manual intervention. Enhancing the accuracy of tracking returned goods, which is critical for refurbishing or recycling. Example: BMW’s Use of RFID in .

We’ll see how it can really help your business. Table of Contents. Key Takeaways. RFID integration with WMS significantly boosts product tracking and inventory counting speed, ensuring more accurate warehouse operations.

where are rfid chips used

what makes something rfid

printer with rfid reader

Technology Used In MultiClass Readers. MultiClass readers are added to the iClass and Prox readers of HID Global to ensure that they work with newer systems without compatibility issues. It is built on the same platform as .Posted on Nov 1, 2021 12:10 PM. On your iPhone, open the Shortcuts app. Tap on the Automation tab at the bottom of your screen. Tap on Create Personal Automation. Scroll down and select NFC. Tap on Scan. Put your iPhone near the NFC tag. Enter a name for your tag. .

1 what is the role of rfid chips in logistics|what does rfid look like