what is the role of rfid chips in logistics An RFID reader is used when items are moved to the warehouse and into the warehouse management system. RFID provides real-time data on supply chain operations, such as the location of goods, the status of shipments, and the performance of supply chain partners. NFC tags are passive data stores that can be read and under some circumstances written to, by an NFC device. Typically, they contain data and are read-only in normal use, but may be rewritable. Apps include secure .

0 · where are rfid chips used

1 · what makes something rfid

2 · what does rfid look like

3 · types of rfid chips

4 · rfid is involved when using

5 · rfid for personal use

6 · how does rfid scanning work

7 · how do rfid chips work

It means that your NFC (Near Field Communication) is turned on and your phone has come into contact with an NFC-enabled device or credit/debit card. If it is enabled, the NFC sensor will look for magnetic objects within its .

RFID provides logistics managers with multiple ways to track and manage products and assets in the supply chain. RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications .

RFID solves some of the biggest challenges in supply-chain management and logistics, including: Capturing, organizing, storing and analyzing large sums of data. Reducing .

During the logistics transportation process, RFID provides real-time tracking information for every link in the goods’ journey. From cargo loading and transportation to delivery, the RFID system .

RFID provides logistics managers with multiple ways to track and manage products and assets in the supply chain. RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation.

An RFID reader is used when items are moved to the warehouse and into the warehouse management system. RFID provides real-time data on supply chain operations, such as the location of goods, the status of shipments, and the performance of supply chain partners.

RFID solves some of the biggest challenges in supply-chain management and logistics, including: Capturing, organizing, storing and analyzing large sums of data. Reducing labor costs and human error. Lowering operational costs. Accelerating the flow of goods. More effectively using working capital. Mitigating security risks.During the logistics transportation process, RFID provides real-time tracking information for every link in the goods’ journey. From cargo loading and transportation to delivery, the RFID system can automatically record data at each stage and issue early warnings when necessary. Discover the role and benefits of RFID in supply chain management, which is a type of tracking technology that stores data in tags attached to products. Enhanced security with RFID tags is quickly becoming a must-have upgrade in logistics and warehousing operations. By embedding RFID chips in their items, companies are able to keep track of them at any time.

By tracking and managing goods in real-time, RFID can effectively improve logistics efficiency, reduce errors and reduce costs. This article will provide a comprehensive guide for beginners, detailing the application, implementation steps, and advantages of RFID in logistics, as well as helping users better understand and utilize RFID .RFID plays a crucial role in cold chain management by: Using temperature-sensitive RFID tags to monitor and log environmental conditions. Providing end-to-end visibility across the cold chain, helping companies avoid product recalls. RFID speeds up tracking and keeps counts more accurate. It helps in getting products to customers sooner. This new way of doing things also changes how we look at costs. With RFID, we can do many tasks faster and with less people. This means up to 60% fewer tasks for people to do by hand.

RFID-powered solutions facilitate seamless proof of delivery through automated scans, reducing disputes and enhancing customer satisfaction. RFID helps streamline sorting, loading, and routing, thereby minimizing delivery times and optimizing resource allocation. RFID provides logistics managers with multiple ways to track and manage products and assets in the supply chain. RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. An RFID reader is used when items are moved to the warehouse and into the warehouse management system. RFID provides real-time data on supply chain operations, such as the location of goods, the status of shipments, and the performance of supply chain partners. RFID solves some of the biggest challenges in supply-chain management and logistics, including: Capturing, organizing, storing and analyzing large sums of data. Reducing labor costs and human error. Lowering operational costs. Accelerating the flow of goods. More effectively using working capital. Mitigating security risks.

During the logistics transportation process, RFID provides real-time tracking information for every link in the goods’ journey. From cargo loading and transportation to delivery, the RFID system can automatically record data at each stage and issue early warnings when necessary.

rfid reader pcsc

Discover the role and benefits of RFID in supply chain management, which is a type of tracking technology that stores data in tags attached to products.

Enhanced security with RFID tags is quickly becoming a must-have upgrade in logistics and warehousing operations. By embedding RFID chips in their items, companies are able to keep track of them at any time.By tracking and managing goods in real-time, RFID can effectively improve logistics efficiency, reduce errors and reduce costs. This article will provide a comprehensive guide for beginners, detailing the application, implementation steps, and advantages of RFID in logistics, as well as helping users better understand and utilize RFID .

where are rfid chips used

RFID plays a crucial role in cold chain management by: Using temperature-sensitive RFID tags to monitor and log environmental conditions. Providing end-to-end visibility across the cold chain, helping companies avoid product recalls. RFID speeds up tracking and keeps counts more accurate. It helps in getting products to customers sooner. This new way of doing things also changes how we look at costs. With RFID, we can do many tasks faster and with less people. This means up to 60% fewer tasks for people to do by hand.

what makes something rfid

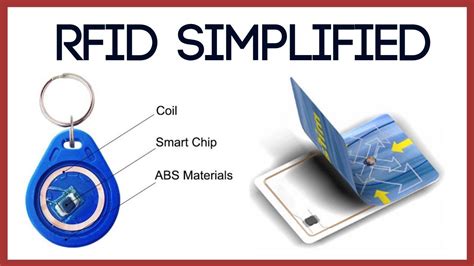

what does rfid look like

$2,495.00

what is the role of rfid chips in logistics|types of rfid chips