wet inlay rfid RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any . $19.99

0 · wet rfid vs dry inlay

1 · rfid vs wet inlays

2 · rfid tags for zebra printers

3 · rfid lost freight labels 4x6

4 · rfid labels for zebra printers

5 · rfid inlays means

6 · rfid inlay manufacturers

7 · rfid catalog

A 90 second tutorial from Seritag on how to read NFC tags with an iPhone 7, 8 or X. Which App to use, what NFC tags you need and what you need to check for. .

RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any .The Vulcan RFID Flame UHF RFID White Wet Inlay is equipped with the optimal, .RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is .RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost every RFID Wet Inlay on the market, including the Smartrac Dogbone and Alien Squiggle.

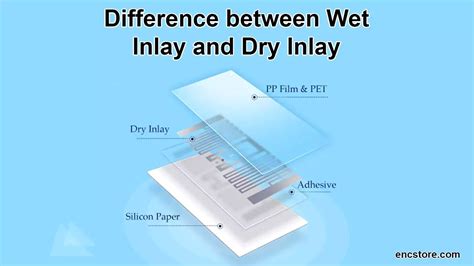

In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment. Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.

Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.The Avery Dennison Smartrac DogBone RFID Wet Inlays excel with superior performance inside of demanding environments and on tough-to-tag materials, due to the inlay's exceptional tolerance against the detuning effect of high dielectric materials.

gemalto pc express card smart card reader

Wet inlay RFID tags are a type of RFID (Radio Frequency Identification) tag consisting of an integrated circuit (IC) chip attached to an antenna, which is then sandwiched between two layers of material, usually paper or plastic.RFID wet inlay is one of the basic components of RFID technology. It consists of a chip, an antenna, and a layer of adhesive backing, but does not contain an outer protective material or substrate. It was originally designed to provide flexibility and ease of integration for a variety of complex application scenarios.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .The NFC Wet Inlay is a smartphone compliant, NFC RFID inlay, optimized for growing a number of RFID tagging applications requiring close range (near field) communication. Near field communication (NFC) inlays, tags, and labels are ideal for use in .

RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost every RFID Wet Inlay on the market, including the Smartrac Dogbone and Alien Squiggle.RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost every RFID Wet Inlay on the market, including the Smartrac Dogbone and Alien Squiggle.In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment. Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.

Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.

The Avery Dennison Smartrac DogBone RFID Wet Inlays excel with superior performance inside of demanding environments and on tough-to-tag materials, due to the inlay's exceptional tolerance against the detuning effect of high dielectric materials.

Wet inlay RFID tags are a type of RFID (Radio Frequency Identification) tag consisting of an integrated circuit (IC) chip attached to an antenna, which is then sandwiched between two layers of material, usually paper or plastic.RFID wet inlay is one of the basic components of RFID technology. It consists of a chip, an antenna, and a layer of adhesive backing, but does not contain an outer protective material or substrate. It was originally designed to provide flexibility and ease of integration for a variety of complex application scenarios.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .The NFC Wet Inlay is a smartphone compliant, NFC RFID inlay, optimized for growing a number of RFID tagging applications requiring close range (near field) communication. Near field communication (NFC) inlays, tags, and labels are ideal for use in .

wet rfid vs dry inlay

Adafruit Industries, Unique & fun DIY electronics and kits Adafruit PN532 NFC/RFID Controller Shield for Arduino + Extras : ID 789 - We've taken our .

wet inlay rfid|rfid vs wet inlays