smart card production As a National eID card, smart health card, residence permit, or electronic passport, smart card . Alabama vs. Auburn. November 25 at 3:30pm ET. Auburn broadcast (Ch. 961) on the SiriusXM app or (Ch. 190) in your vehicle. Alabama broadcast (Ch. 81) on the SiriusXM app or (Ch. 81) in your vehicle. National .

0 · smart cards used at banks

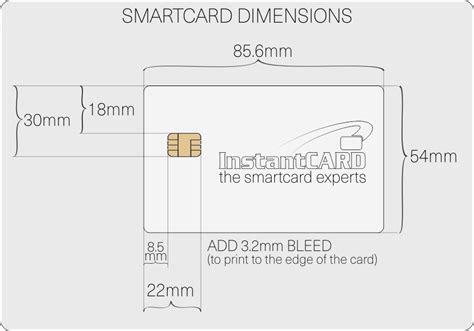

1 · smart card size in mm

2 · smart card manufacturing

3 · smart card manufacturer in kazakhstan

4 · microprocessor smart card

5 · memory based smart card

6 · how to make smart card

7 · contact and contactless smart cards

The Drive with Bill Cameron, ESPN 106.7’s weekday afternoon sports show, is a fast-paced, in-depth look at the world of sports with a focus on Auburn University and local high schools. Live .

As a National eID card, smart health card, residence permit, or electronic passport, smart card . The production of smart card modules is a complex and meticulously orchestrated process that combines advanced technology with precision engineering. From chip embedding to final inspection,.

As a National eID card, smart health card, residence permit, or electronic passport, smart card technology offers more robust identification and authentication tools for both authorities' and citizens' benefits.

The most comprehensive book on state-of-the-art smart card technology available. Updated with new international standards and specifications, this essential fourth edition now covers all aspects of smart card in a completely revised structure.CardLogix offers an extensive portfolio of in-house smart chip card programming services from simple scripts for I2C non-volatile memory cards to loading Java applets, variable data, and formatting card operating systems.

Smart card bodies are typically crafted from a combination of PVC, PET, or polycarbonate. These materials are chosen for their durability, flexibility, and compatibility with the card's . Smart card production entails a broad selection of activities and technologies. It begins with printing, laminating or injection moulding of the card body and the application of several card related items such as magnetic stripes and holograms.

smart cards used at banks

This practical guide bridges the gap between smart card applications and software, providing an accessible introduction to a versatile technology. Featuring: Step-by-step descriptions of the production processes for chip modules, traditional, contactless and dual-interface smart cards.

Production methods depend upon the specific application of the final card. Methods of production are outlined and examples of production mechanisms are illustrated. Production methods for contactless smart cards and dual interface smart cards with different antenna technologies are covered.Detailed coverage of the practicalities and mechanics of smart card manufacture will appeal to a range of software developers, practitioners and students from within the electronics, security, and communications arenas.

This chapter gives an introduction to the production steps in the lifecycle of a (smart) card. After a short introduction the manufacturing of the card body will be described.

The production of smart card modules is a complex and meticulously orchestrated process that combines advanced technology with precision engineering. From chip embedding to final inspection,.

smart card size in mm

As a National eID card, smart health card, residence permit, or electronic passport, smart card technology offers more robust identification and authentication tools for both authorities' and citizens' benefits.

The most comprehensive book on state-of-the-art smart card technology available. Updated with new international standards and specifications, this essential fourth edition now covers all aspects of smart card in a completely revised structure.CardLogix offers an extensive portfolio of in-house smart chip card programming services from simple scripts for I2C non-volatile memory cards to loading Java applets, variable data, and formatting card operating systems.

Smart card bodies are typically crafted from a combination of PVC, PET, or polycarbonate. These materials are chosen for their durability, flexibility, and compatibility with the card's . Smart card production entails a broad selection of activities and technologies. It begins with printing, laminating or injection moulding of the card body and the application of several card related items such as magnetic stripes and holograms.

This practical guide bridges the gap between smart card applications and software, providing an accessible introduction to a versatile technology. Featuring: Step-by-step descriptions of the production processes for chip modules, traditional, contactless and dual-interface smart cards. Production methods depend upon the specific application of the final card. Methods of production are outlined and examples of production mechanisms are illustrated. Production methods for contactless smart cards and dual interface smart cards with different antenna technologies are covered.

Detailed coverage of the practicalities and mechanics of smart card manufacture will appeal to a range of software developers, practitioners and students from within the electronics, security, and communications arenas.

smart card manufacturing

barcode scanner vs rfid scanner

multi rfid scanner arduino

Auburn Sports Network game day coverage begins three hours prior to kickoff. .

smart card production|contact and contactless smart cards