injection mold rfid tracking Boni Global’s Mold Tracking Solution allows for zone-based tracking with BLE-powered devices or passive RFID tags that are small, easily mountable and durable against the high temperatures and repeated cycles of the injection molding processes. Get the best deals for zelda amiibo nfc cards at eBay.com. We have a great online selection at .

0 · rfid injection molding

1 · injection molding plastic parts

It may sound complicated, but bear with me and you will see the process step by step! Prerequisites: in order to complete the process you will need an Android device with NFC, your Amiibo, and NTAG215 .

Würth Elektronik, a German company that manufactures printed circuit boards, has developed .Boni Global’s Mold Tracking Solution allows for zone-based tracking with BLE-powered .Würth Elektronik, a German company that manufactures printed circuit boards, has developed a tag that can withstand the injection-molding process, so it can be embedded in crates (see Würth Elektronik Manufactures a Tougher Breed of Tag).Boni Global’s Mold Tracking Solution allows for zone-based tracking with BLE-powered devices or passive RFID tags that are small, easily mountable and durable against the high temperatures and repeated cycles of the injection molding processes.

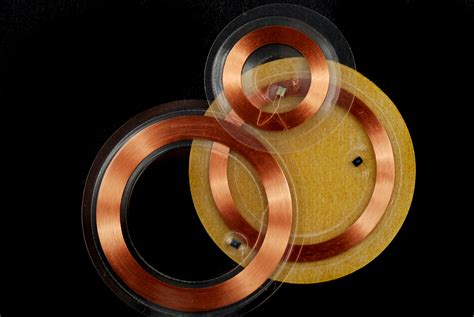

Did you know that Radio Frequency Identification (RFID) can be a powerful tool for protecting and tracking valuable injection molded parts and components? RFID systems use radio waves to transfer data, making them highly effective in a variety of environments.

The main benefits of RFID for mold management in injection molding include: Automated Tracking: Eliminates manual data entry by tracking mold location and usage in real time. Predictive Maintenance: Helps identify maintenance . The goal of a RFID injection mold label (RFID IML) convertor is to produce RFID IML’s that enable end-users to meet or exceed performance, cost, workability, safety and timing requirements regardless of circumstance.

In-mold labels (IML) provide a durable and integrated solution for labeling plastic containers and products during the molding process. Embedded directly during molding for maximum durability. Available with RFID technology for advanced tracking.Embeddable RFID Tags for Manufacturing are designed to be injection-molded by OEMs and suppliers into their consumables, parts, and systems. By adding RFID capabilities at point-of-manufacture , they enable the digitization of integrated supply chains with real-time information and added flexibility.Identify, protect and track valuable assets with embedded RFID. Texas Injection Molding collaborates with leading RFID hardware and Systems Integrators to bring the experience of plastic injection molding to embedded RFID.Mold-Masters SmartMOLD is a cloud-based software platform dedicated to the plastics industry providing real-time data to drive injection molding innovation. Process data is collected from sensors embedded within the injection mold which offers feedback and insights that drive enhanced productivity.

rfid injection molding

This white paper aims at using the example of manufacturing plastics with injection molding machines to describe how Industry 4.0 can quite easily gain entry into production, make processes more efficient and minimize costs.Würth Elektronik, a German company that manufactures printed circuit boards, has developed a tag that can withstand the injection-molding process, so it can be embedded in crates (see Würth Elektronik Manufactures a Tougher Breed of Tag).Boni Global’s Mold Tracking Solution allows for zone-based tracking with BLE-powered devices or passive RFID tags that are small, easily mountable and durable against the high temperatures and repeated cycles of the injection molding processes.

Did you know that Radio Frequency Identification (RFID) can be a powerful tool for protecting and tracking valuable injection molded parts and components? RFID systems use radio waves to transfer data, making them highly effective in a variety of environments.The main benefits of RFID for mold management in injection molding include: Automated Tracking: Eliminates manual data entry by tracking mold location and usage in real time. Predictive Maintenance: Helps identify maintenance . The goal of a RFID injection mold label (RFID IML) convertor is to produce RFID IML’s that enable end-users to meet or exceed performance, cost, workability, safety and timing requirements regardless of circumstance.In-mold labels (IML) provide a durable and integrated solution for labeling plastic containers and products during the molding process. Embedded directly during molding for maximum durability. Available with RFID technology for advanced tracking.

Embeddable RFID Tags for Manufacturing are designed to be injection-molded by OEMs and suppliers into their consumables, parts, and systems. By adding RFID capabilities at point-of-manufacture , they enable the digitization of integrated supply chains with real-time information and added flexibility.

Identify, protect and track valuable assets with embedded RFID. Texas Injection Molding collaborates with leading RFID hardware and Systems Integrators to bring the experience of plastic injection molding to embedded RFID.

Mold-Masters SmartMOLD is a cloud-based software platform dedicated to the plastics industry providing real-time data to drive injection molding innovation. Process data is collected from sensors embedded within the injection mold which offers feedback and insights that drive enhanced productivity.

business rfid card keys systems

berkeley cal1card rfid reader

injection molding plastic parts

FeliCa Products Learn more ; Latest News. Latest News List; August 26, 2024 NFC Port Software Update February 21, 2024 NFC Port Software Update August 1, 2023 NFC Port Software Update June 15, 2023 USB NFC Reader RC .

injection mold rfid tracking|rfid injection molding