smart card raw material Smart card bodies are typically crafted from a combination of PVC, PET, or polycarbonate. These materials are chosen for their durability, flexibility, and compatibility with the card's. Simply NFC is the most powerful, simple, and accessible NFC writer/reader available. Simply tap the “Read NFC” button to start scanning for NFC tags .

0 · Smart Card Materials Market Size Report, 2030

1 · Smart Card Materials Market Size Repo

2 · Smart Card Material Market Worth US$

3 · Smart Card Material Market Forecast an

4 · How Smart Cards are Made

Step 1. Go to Settings > Connections > NFC and contactless payments. Step 2. Tap Contactless payments, and then select your preferred payment app. * Image shown is for illustration purposes only. Step 3. Additional payment apps can .Posted on Nov 1, 2021 12:10 PM. On your iPhone, open the Shortcuts app. Tap on the Automation tab at the bottom of your screen. Tap on Create Personal Automation. Scroll down and select NFC. Tap on Scan. Put your iPhone near the NFC tag. Enter a name for your tag. .

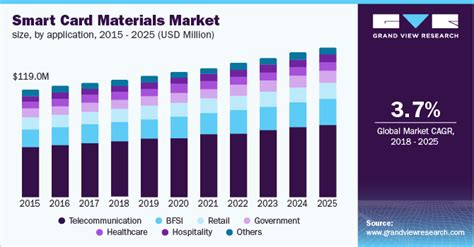

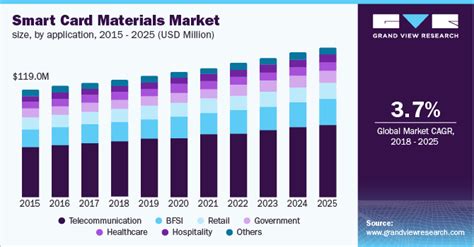

The global smart card materials market size was valued at USD 1.11 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2024 to 2030

Smart card bodies are typically crafted from a combination of PVC, PET, or polycarbonate. These materials are chosen for their durability, flexibility, and compatibility with the card's.The global smart card materials market size was valued at USD 1.11 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2024 to 2030The polyvinyl chloride segment held the largest share of the global smart card material market in 2021. Polyvinyl chloride is the most common and strong plastic material used for card manufacturing. The material is used for contact and contactless cards.Smart Card Materials Market - By Raw Material Polyethylene terephthalate-glycol (PETG) dominated the raw materials segment in 2021. Its superior properties like durability, chemical resistance, and formability make it an excellent choice in the manufacturing of smart cards.

Materials such as PETG, ABS, PVC, PC, and PET are used for the manufacturing of smart card bodies, and they provide the required thickness and durability to smart cards. These.At the core of any smart card is the material you choose – it defines the strength, durability and sustainability of your cards. Historically smart cards have been manufactured using a range of plastic materials such as PVC, PET, PETG, PC and ABS, but the push towards more eco-friendly choices has seen us introduce a wide range of eco .

Smart Card Materials Market Size Report, 2030

Smart cards consist of several layers, with the smart card module being the core component. This module typically contains a microprocessor or memory chip, surrounded by layers of substrate and.The Smart Card Materials Market faces constraints due to several factors. One significant restraint is the limited availability and fluctuating costs of raw materials such as PVC, PET, and polycarbonate, impacting production scalability and profitability. More and more banks, corporations and smart card manufacturers around the world are using sustainable plastics. To follow this important trend, there is a promising innovation for identity documents, Parley Ocean Plastic, that will help to .

Fluctuation in the prices of raw materials that are used as chemicals to manufacture the smart cards is the biggest market growth restraining factor. Threats like fraudulent activities and security-related issues are other factors that may come in the way of . Smart card bodies are typically crafted from a combination of PVC, PET, or polycarbonate. These materials are chosen for their durability, flexibility, and compatibility with the card's.The global smart card materials market size was valued at USD 1.11 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2024 to 2030The polyvinyl chloride segment held the largest share of the global smart card material market in 2021. Polyvinyl chloride is the most common and strong plastic material used for card manufacturing. The material is used for contact and contactless cards.

Smart Card Materials Market - By Raw Material Polyethylene terephthalate-glycol (PETG) dominated the raw materials segment in 2021. Its superior properties like durability, chemical resistance, and formability make it an excellent choice in the manufacturing of smart cards.

Materials such as PETG, ABS, PVC, PC, and PET are used for the manufacturing of smart card bodies, and they provide the required thickness and durability to smart cards. These.At the core of any smart card is the material you choose – it defines the strength, durability and sustainability of your cards. Historically smart cards have been manufactured using a range of plastic materials such as PVC, PET, PETG, PC and ABS, but the push towards more eco-friendly choices has seen us introduce a wide range of eco . Smart cards consist of several layers, with the smart card module being the core component. This module typically contains a microprocessor or memory chip, surrounded by layers of substrate and.The Smart Card Materials Market faces constraints due to several factors. One significant restraint is the limited availability and fluctuating costs of raw materials such as PVC, PET, and polycarbonate, impacting production scalability and profitability.

More and more banks, corporations and smart card manufacturers around the world are using sustainable plastics. To follow this important trend, there is a promising innovation for identity documents, Parley Ocean Plastic, that will help to .

Smart Card Materials Market Size Repo

Former Auburn quarterback Charlie Trotman worked in the role from 1980-2000, before being succeeded by Stan White. “Stan has given the last 22 years of his life, in part, to .

smart card raw material|Smart Card Materials Market Size Report, 2030