manufacturing process of rfid tags RFID Tags. These are the way the device or asset will communicate with the system. RFID Tags can be either active or passive, the former has a battery so is always on or ‘active’ whereas passive is only powered up when it is scanned. This guide will look at setting up an NFC System with a Raspberry Pi using the Waveshare PN542 NFC HAT. This also comes with a Type 2 Tag (NTAG215) Keychain Fob making it a complete package to get up and running. The HAT connects directly to the top of the Raspberry Pi GPIO and is a great way to read an NFC chip.

0 · what is an rfid operator

1 · rfid tracking systems for manufacturing

2 · rfid tag components

3 · rfid production tracking system

4 · rfid manufacturing inventory management

5 · rfid manufacturing companies

6 · how to make rfid tag

7 · diy rfid tag

Here's everything you need to know to tune into today’s matchup between Arkansas and Auburn in Bud Walton Arena. 247Sports. 247Sports Home; FB Rec . Arkansas +2.5/+120. RADIO: Sirius Ch. 119 .Statewide coverage is the hallmark of the Auburn Sports Network's exclusive coverage of Auburn football. All home and away games are broadcast across the entire state .

Manufacturing, in particular, calls for the heavy integration of RFID solutions, .Discover how RFID tags are manufactured. From antenna creation to chip installation and . RFID Tags. These are the way the device or asset will communicate with the system. RFID Tags can be either active or passive, the former has a battery so is always on or ‘active’ whereas passive is only powered up when it is scanned.

Manufacturing, in particular, calls for the heavy integration of RFID solutions, which can make a dramatic difference by enabling real-time visibility and automation for critical processes. From production to inventory management, these tags are quickly becoming crucial every step of the way.

Discover how RFID tags are manufactured. From antenna creation to chip installation and quality testing, learn how RFID technology is crafted and what innovations shape its future. Explore key challenges and advancements in RFID tag production.There are three different components of an RFID tag: an RFID chip, comprised of an integrated circuit (IC), an antenna and an underlying layer/base (known as the substrate). These components are not typically created in house by the tag manufacturers, instead workload is spread out to other manufacturers.

The production process of RFID tags begins at the design stage. Designers need to determine the size, shape, operating frequency, and performance indicators of the tag based on actual application requirements.

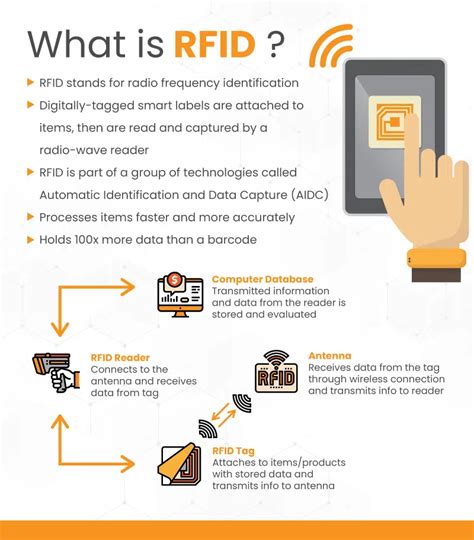

In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.Learn the stages and key concepts of RAIN RFID and NFC tag production process. Get an overview of quality testing and encoding tools.Radio-frequency Identification (RFID) technology enables retailers to identify items using radio waves. It transmits data from an RFID tag to a reader, providing accurate, real-time inventory tracking. RFID consists of two main components: tags and readers. A reader with one or more antennas sends and receives electromagnetic signals from RFID .

RFID tags attached to products or containers automatically capture data as they pass through RFID reader zones, allowing production managers to track production milestones and identify potential bottlenecks.RFID electronic tag die-cutting is an essential step in the manufacturing process. It ensures the proper shape, size, and functionality of the RFID tags, while also allowing for efficient and scalable production. RFID Tags. These are the way the device or asset will communicate with the system. RFID Tags can be either active or passive, the former has a battery so is always on or ‘active’ whereas passive is only powered up when it is scanned.

Manufacturing, in particular, calls for the heavy integration of RFID solutions, which can make a dramatic difference by enabling real-time visibility and automation for critical processes. From production to inventory management, these tags are quickly becoming crucial every step of the way.Discover how RFID tags are manufactured. From antenna creation to chip installation and quality testing, learn how RFID technology is crafted and what innovations shape its future. Explore key challenges and advancements in RFID tag production.There are three different components of an RFID tag: an RFID chip, comprised of an integrated circuit (IC), an antenna and an underlying layer/base (known as the substrate). These components are not typically created in house by the tag manufacturers, instead workload is spread out to other manufacturers.

The production process of RFID tags begins at the design stage. Designers need to determine the size, shape, operating frequency, and performance indicators of the tag based on actual application requirements. In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.

Learn the stages and key concepts of RAIN RFID and NFC tag production process. Get an overview of quality testing and encoding tools.Radio-frequency Identification (RFID) technology enables retailers to identify items using radio waves. It transmits data from an RFID tag to a reader, providing accurate, real-time inventory tracking. RFID consists of two main components: tags and readers. A reader with one or more antennas sends and receives electromagnetic signals from RFID . RFID tags attached to products or containers automatically capture data as they pass through RFID reader zones, allowing production managers to track production milestones and identify potential bottlenecks.

what is an rfid operator

rfid tracking systems for manufacturing

rfid tag components

November 7, 2024. It’s officially Week 11 of the college football season, and the Washington Huskies are set to take on the Penn State Nittany Lions this Saturday night at 8pm ET. .

manufacturing process of rfid tags|diy rfid tag