rfid chips in inventory RFID inventory tracking involves labeling each item with an electronic chip that transmits data wirelessly from the tag to the reader. This technology is used to track items from production to point-of-sale and is beneficial in optimizing inventories for retailers, manufacturers, and wholesalers.

Hit the LOAD TAG button and select your Amiibo.bin dump file. Make sure any Amiibo are UNZIPPED you can put them all into their own folder called AMIIBO if you wish makes it easier. Click on WRITE TAG. Place your .

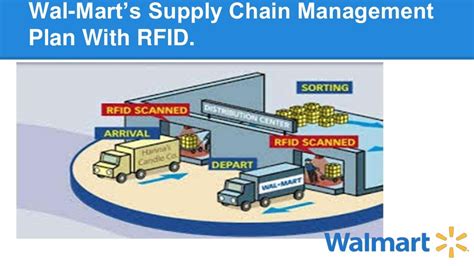

0 · walmart rfid inventory system

1 · walmart rfid inventory

2 · rfid warehouse inventory system

3 · rfid inventory tracking system

4 · rfid inventory tracking

5 · rfid inventory companies

6 · rfid for warehouse inventory

7 · pros and cons of rfid

This can be a contactless card, a smartphone with a mobile wallet app, or a wearable device with contactless payment capabilities. 2. Near Field Communication (NFC): Contactless payments utilize NFC technology for .Most of the time these NFC cards are using encryption so it is not possible to emulate them unless you can figure out the encryption key used. And finding the encryption key would make .

RFID inventory tracking involves labeling each item with an electronic chip that transmits data wirelessly from the tag to the reader. This technology is used to track items from production to point-of-sale and is beneficial in optimizing inventories for retailers, .Any organization can benefit from asset tracking technology in some capacity. .

She has developed a deep understanding of RFID and barcode technologies and .Asset Vue, LLC is a Paoli, Pennsylvania-based provider of RFID-enabled asset .

Discover the benefits of using a smart RFID cabinet for automated inventory and self . RFID inventory tracking involves labeling each item with an electronic chip that transmits data wirelessly from the tag to the reader. This technology is used to track items from production to point-of-sale and is beneficial in optimizing inventories for retailers, manufacturers, and wholesalers. Radio-frequency identification (RFID) technology is a way for retailers to identify items using radio waves. It transmits data from a RFID tag to a reader, giving you accurate, real-time tracking data of your inventory.Effectively tracking food products at the item and case level helps ensure accurate inventory management, allowing for improved food safety, recall readiness, and supply chain visibility. RFID technology can enable this tracking by capturing needed attribute data without a line of sight.

RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time.

RFID inventory tracking effectively monitors items in real-time by labeling each item with an electronic chip. It uses wireless communication to transmit data from tag to reader and helps track items from production to point-of-sale.

How to Track Your Inventory with an RFID Inventory Management System. In this manual, we've broken down the steps necessary to make your inventory counting worthwhile. The direction we laid out here is easily scalable regardless of the size and industry you are in.RFID – or Radio Frequency Identification – is technology controlled by radio waves. Individual RFID tags can communicate with reader devices, even when those devices are not within line-of-site. The reader can then share that data with software, like . An RFID (radio frequency identification) inventory management system helps with inventory visibility, particularly when using mass production. RFID technology can automate many inventory-related processes, such as stocktaking, reordering, and item tracking. Here, Radio Frequency Identification (RFID) technology provides an elevated level of oversight and control over inventory. RFID technology leverages radio waves to read and capture data stored on a tag affixed to an object.

Radio Frequency Identification (RFID) is a type of technology that retailers can use to manage their inventory. It works by using RFID tags which contain electronically stored information, such as stock keeping unit (SKU) numbers, product prices, and stock levels. The retailer can then use an RFID reader to find this data quickly and efficiently. RFID inventory tracking involves labeling each item with an electronic chip that transmits data wirelessly from the tag to the reader. This technology is used to track items from production to point-of-sale and is beneficial in optimizing inventories for retailers, manufacturers, and wholesalers. Radio-frequency identification (RFID) technology is a way for retailers to identify items using radio waves. It transmits data from a RFID tag to a reader, giving you accurate, real-time tracking data of your inventory.Effectively tracking food products at the item and case level helps ensure accurate inventory management, allowing for improved food safety, recall readiness, and supply chain visibility. RFID technology can enable this tracking by capturing needed attribute data without a line of sight.

RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time. RFID inventory tracking effectively monitors items in real-time by labeling each item with an electronic chip. It uses wireless communication to transmit data from tag to reader and helps track items from production to point-of-sale.How to Track Your Inventory with an RFID Inventory Management System. In this manual, we've broken down the steps necessary to make your inventory counting worthwhile. The direction we laid out here is easily scalable regardless of the size and industry you are in.

RFID – or Radio Frequency Identification – is technology controlled by radio waves. Individual RFID tags can communicate with reader devices, even when those devices are not within line-of-site. The reader can then share that data with software, like . An RFID (radio frequency identification) inventory management system helps with inventory visibility, particularly when using mass production. RFID technology can automate many inventory-related processes, such as stocktaking, reordering, and item tracking. Here, Radio Frequency Identification (RFID) technology provides an elevated level of oversight and control over inventory. RFID technology leverages radio waves to read and capture data stored on a tag affixed to an object.

walmart rfid inventory system

walmart rfid inventory

rfid warehouse inventory system

rfid inventory tracking system

rfid inventory tracking

With ACR122 NFC Software Development Kit, users can optimize the use of ACR122U/T for their contactless and NFC applications. ACR122 is the world’s first NFC reader compliant with the CCID specification. The ACR122U and its .

rfid chips in inventory|rfid inventory tracking