rfid chips for tooling Industrial RFID systems from Balluff provide you with the analysis data that is indispensable for exact cost calculations and modern quality and tool management. All relevant tool data, such as numbers, dimensions or service life, are saved reliably. And are always available.

You can try NFC Tools or the MiFare Classic Tool to emulate cards from your phone, but in my experience it's too limited. NFC tools can emulate tags but I've tried it with hotel keys and it .

0 · rfid tracking system for tools

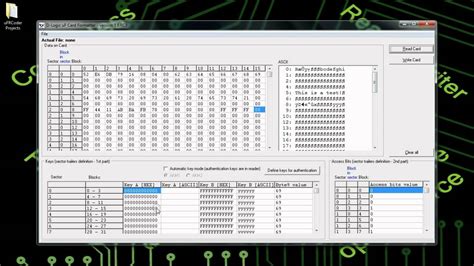

1 · rfid tools windows

2 · rfid tool tracking software

3 · rfid tags for tool tracking

4 · rfid tags for small tools

5 · rfid for tool tracking

6 · 2020 super rfid copier software

7 · 2020 super rfid copier download

Saturday, January 4, 1992NFC: Washington Redskins 24, Atlanta Falcons 7During their regular season meeting, Washington defeated . See more

With Balluff, you benefit from more than 30 years of Industrial RFID expertise. Our systems provide complete tool data with extreme reliability for modern processing centers and guarantee secure operation as well as high productivity of your equipment.Manual entry is eliminated, minimizing the risk of incorrect data. Instead the data is written o.

ToolConnect: RFID System. The ToolConnect RFID System automatically transfers tool .

what is no support for nfc tag

With Balluff, you benefit from more than 30 years of Industrial RFID expertise. Our systems provide complete tool data with extreme reliability for modern processing centers and guarantee secure operation as well as high productivity of your equipment.ToolConnect: RFID System. The ToolConnect RFID System automatically transfers tool presetter measurement data directly to and from the CNC control via RFID tags embedded in tool holders. Tools are measured at the presetter where tool data is written to the RFID tag.Industrial RFID systems from Balluff provide you with the analysis data that is indispensable for exact cost calculations and modern quality and tool management. All relevant tool data, such as numbers, dimensions or service life, are saved reliably. And are always available.CNC/Tooling/Molds. In CNC applications, RFID provides a solution to ensure the right tooling is in place before a process is allowed to begin. Molds have a finite life and RFID sensing provides a method to track which mold is nearing its end of life or which mold is brand new but producing rejected products at a 30% rate.

Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.

rfid tracking system for tools

The RFID chip is written on the setting and measuring device and read in automatically by the machine tool, for companies with modern machinery, ask ZOLLER.RFID in machine tool manufacturing. The Benefits. Reliable identification using the RFID system enables both fully automated and safe operation of CNC machinery. The read heads designed for this application can be installed directly in the metal environment.

NXP Semiconductors launched the NXP ICODE® chip series as a high-frequency (HF) RFID product. It is designed to meet the needs of modern supply chain and asset management. The ICODE chip uses a frequency of 13.56 MHz and targets medium to short-range RFID applications. Its core features include high-speed data transmission, strong anti .Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.

CNC (optional CNC interfaces available) A wide variety of RFID data carriers (chips), read/write heads, processors and accessories are available. Balluff can help you choose the correct RFID parts based on the system capabilities required for the machine and tool holders being used.

With Balluff, you benefit from more than 30 years of Industrial RFID expertise. Our systems provide complete tool data with extreme reliability for modern processing centers and guarantee secure operation as well as high productivity of your equipment.ToolConnect: RFID System. The ToolConnect RFID System automatically transfers tool presetter measurement data directly to and from the CNC control via RFID tags embedded in tool holders. Tools are measured at the presetter where tool data is written to the RFID tag.

Industrial RFID systems from Balluff provide you with the analysis data that is indispensable for exact cost calculations and modern quality and tool management. All relevant tool data, such as numbers, dimensions or service life, are saved reliably. And are always available.

CNC/Tooling/Molds. In CNC applications, RFID provides a solution to ensure the right tooling is in place before a process is allowed to begin. Molds have a finite life and RFID sensing provides a method to track which mold is nearing its end of life or which mold is brand new but producing rejected products at a 30% rate.Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.The RFID chip is written on the setting and measuring device and read in automatically by the machine tool, for companies with modern machinery, ask ZOLLER.

RFID in machine tool manufacturing. The Benefits. Reliable identification using the RFID system enables both fully automated and safe operation of CNC machinery. The read heads designed for this application can be installed directly in the metal environment.NXP Semiconductors launched the NXP ICODE® chip series as a high-frequency (HF) RFID product. It is designed to meet the needs of modern supply chain and asset management. The ICODE chip uses a frequency of 13.56 MHz and targets medium to short-range RFID applications. Its core features include high-speed data transmission, strong anti .

stone island nfc tag

Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.

rfid tools windows

rfid tool tracking software

what is no supported app for this nfc tag

rfid tags for tool tracking

What do the Animal Crossing NFC Cards do? The Animal Crossing NFC cards .

rfid chips for tooling|rfid for tool tracking