copper thin film for rfid uhf antenna on flexible substrate It was found that the resistivity of the thin film is below two times the bulk resistivity of copper for a deposition pressure below 4 × 10−3 mbar and . Making a payment. Log in to the iMobile Pay app and click on ‘Tap to Pay’ on login page or ‘Shop’ section. Select a virtual Visa card to make the payment and wave or tap the phone near the .

0 · Printing of passive RFID tag antennas on flexible substrates for

1 · Fabrication of a Flexible RFID Antenna by Using the Novel

2 · Copper thin film for RFID UHF antenna on flexible substrate

3 · Copper thin film for RFID UHF antenna on flexible

4 · Average thickness and resistivity of copper thin films at 40 W for

5 · Antioxidant high

NYON, Switzerland, Nov. 19, 2020 /PRNewswire/ -- "After being one of the first companies in the world to equip its watches with an electronic warranty in 2009, Hublot is once again innovating with .

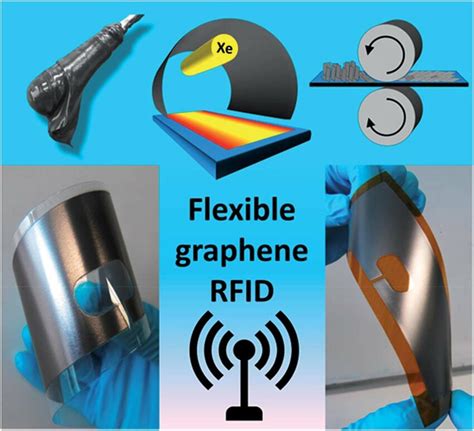

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was .

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen

It was found that the resistivity of the thin film is below two times the bulk resistivity of copper for a deposition pressure below 4 × 10−3 mbar and . The universal applications of as-prepared copper paste in flexible printed electronics (e.g., electromagnetic interference (EMI) shielding films, anti-fog films, and RFID .This paper aims to fill this gap; it focuses on printing UHF tag antennas on flexible substrates and relates the antenna performance with the printed layer properties. It considers two laboratory .

Made available by U.S. Department of Energy Office of Scientific and Technical Information . The techniques used to fabricate RFID antennas for UHF band applications are contrasted in Figure 8 and Table 2. We compare a novel additive procedure that utilizes the . A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was .Copper thin film for RFID UHF antenna on flexible substrate. Article. Full-text available. Aug 2010. Nhan Ai Tran. Huy Nam Tran. Chien Mau Dang. Eric Fribourg-Blanc. A process.

Printing of passive RFID tag antennas on flexible substrates for

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its flexibility at laboratory scale.A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosenIt was found that the resistivity of the thin film is below two times the bulk resistivity of copper for a deposition pressure below 4 × 10−3 mbar and thickness above 450 nm. These results enable the reliable fabrication of copper RFID UHF antennae on .

Fabrication of a Flexible RFID Antenna by Using the Novel

The universal applications of as-prepared copper paste in flexible printed electronics (e.g., electromagnetic interference (EMI) shielding films, anti-fog films, and RFID tags) via screen.This paper aims to fill this gap; it focuses on printing UHF tag antennas on flexible substrates and relates the antenna performance with the printed layer properties. It considers two laboratory-scale additive printing techniques most used in research: inkjet printing and screen printing.

Made available by U.S. Department of Energy Office of Scientific and Technical Information . The techniques used to fabricate RFID antennas for UHF band applications are contrasted in Figure 8 and Table 2. We compare a novel additive procedure that utilizes the galvanic displacement reaction of PET film to the conventional subtractive method, which involves etching copper foil.

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its.Copper thin film for RFID UHF antenna on flexible substrate. Article. Full-text available. Aug 2010. Nhan Ai Tran. Huy Nam Tran. Chien Mau Dang. Eric Fribourg-Blanc. A process.Copper thin film for RFID UHF antenna on flexible substrate 🔍 IOP Publishing; Institute of Physics Publishing (IOP) (ISSN 2043-6254), Advances in Natural Sciences: Nanoscience and Nanotechnology, #2, 1, pages 025016-, 2010 jun 01

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its flexibility at laboratory scale.A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosenIt was found that the resistivity of the thin film is below two times the bulk resistivity of copper for a deposition pressure below 4 × 10−3 mbar and thickness above 450 nm. These results enable the reliable fabrication of copper RFID UHF antennae on .

The universal applications of as-prepared copper paste in flexible printed electronics (e.g., electromagnetic interference (EMI) shielding films, anti-fog films, and RFID tags) via screen.This paper aims to fill this gap; it focuses on printing UHF tag antennas on flexible substrates and relates the antenna performance with the printed layer properties. It considers two laboratory-scale additive printing techniques most used in research: inkjet printing and screen printing.Made available by U.S. Department of Energy Office of Scientific and Technical Information .

iphone 13 pro nfc reader location

The techniques used to fabricate RFID antennas for UHF band applications are contrasted in Figure 8 and Table 2. We compare a novel additive procedure that utilizes the galvanic displacement reaction of PET film to the conventional subtractive method, which involves etching copper foil.

A process flow using photolithography and sputtering was studied for copper antenna fabrication on thin poly(ethylene terephthalate) (PET) substrate. The lift-off route was chosen for its.Copper thin film for RFID UHF antenna on flexible substrate. Article. Full-text available. Aug 2010. Nhan Ai Tran. Huy Nam Tran. Chien Mau Dang. Eric Fribourg-Blanc. A process.

Copper thin film for RFID UHF antenna on flexible substrate

$20.00

copper thin film for rfid uhf antenna on flexible substrate|Antioxidant high