smart card module assembly This module describes the fundamentals of smart card technology and uses. After reviewing . On 27 January 2012, Nintendo President Satoru Iwata announced in a briefing that the controller of the Wii U home console will have an installable NFC function. By installing this . See more

0 · smart card production technology

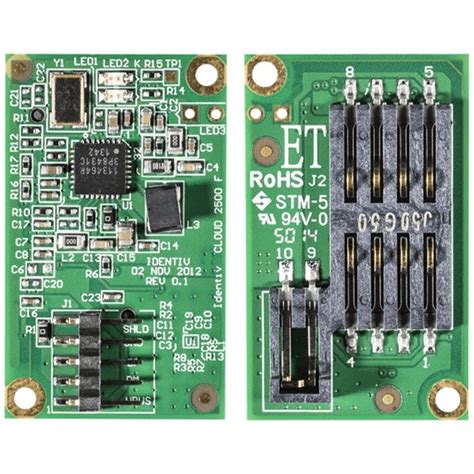

1 · Smart card modules

2 · Smart Cards

3 · Module 1: Smart Card Fundamentals

4 · How Smart Cards are Made – Part 1: Smart Card Module Production

The nRF52832 and nRF52840 devices have a built-in NFC radio which can be .

The smart card module assembly and flip chip inlay manufacturing lines can support a variety .the smart card milling system sCm 5001 is used for automatic milling of cavities for iC modules .

This module describes the fundamentals of smart card technology and uses. After reviewing .Smart card dual-interface modules. The products and services spectrum of the Security .

The smart card module assembly and flip chip inlay manufacturing lines can support a variety of end market applications including financial, banking, government, health, retail, transportation and telecoms. Smart cards consist of several layers, with the smart card module being the core component. This module typically contains a microprocessor or memory chip, surrounded by layers of.the smart card milling system sCm 5001 is used for automatic milling of cavities for iC modules in plastic cards. the system is perfectly suitable for all contact cards, dual interface cards and multi-sim cards. this system features a highly economical card milling process for medium to large sized production tasks.This module describes the fundamentals of smart card technology and uses. After reviewing this module, CSCIP applicants should be able to answer the following questions: What are common smart card-based applications? What are the different types .

Smart card dual-interface modules. The products and services spectrum of the Security Packaging Center ranges from chip card modules for memories and controller ICs, modules for security ICs, customer specific package solutions and contract assembly.

Smartware is pleased to introduce assemblies based on the new US-PICC2 board. The US-4P_SMB (4 contactless heads) and US-4P4I (4 combi heads) are designed to address all contactless cards whatever is the chip manufacturer or the antenna technology.

Wirebonded smart card modules are typically going through the following process: Dispense die attach. Place die on the substrate and Heat Cure. Wire bonding. Apply encapsulant and Cure (Heat or UV) Dimension and position of Encapsulation.Working in partnership with smart card market leaders since 1996, we provide hi-tech adhesive solutions for all bonding and assembly needs. In fact, more than two billion cards a year already use our films for module embedding, satisfying the increasing demand for secured data.Module embedding is the process of adding a smart chip, either memory or micro-controller, to a plastic card by milling a profile into the card and bonding the module in place. Our automated solution is able to produce many thousands of cards per day from our Technical Centre.Smart cards, or else chip cards or integrated circuit cards (ICCs), may include an integrated smart card module (also referred to as chip module) having at least one chip. The smart card.

The smart card module assembly and flip chip inlay manufacturing lines can support a variety of end market applications including financial, banking, government, health, retail, transportation and telecoms. Smart cards consist of several layers, with the smart card module being the core component. This module typically contains a microprocessor or memory chip, surrounded by layers of.the smart card milling system sCm 5001 is used for automatic milling of cavities for iC modules in plastic cards. the system is perfectly suitable for all contact cards, dual interface cards and multi-sim cards. this system features a highly economical card milling process for medium to large sized production tasks.This module describes the fundamentals of smart card technology and uses. After reviewing this module, CSCIP applicants should be able to answer the following questions: What are common smart card-based applications? What are the different types .

Smart card dual-interface modules. The products and services spectrum of the Security Packaging Center ranges from chip card modules for memories and controller ICs, modules for security ICs, customer specific package solutions and contract assembly.Smartware is pleased to introduce assemblies based on the new US-PICC2 board. The US-4P_SMB (4 contactless heads) and US-4P4I (4 combi heads) are designed to address all contactless cards whatever is the chip manufacturer or the antenna technology.Wirebonded smart card modules are typically going through the following process: Dispense die attach. Place die on the substrate and Heat Cure. Wire bonding. Apply encapsulant and Cure (Heat or UV) Dimension and position of Encapsulation.

Working in partnership with smart card market leaders since 1996, we provide hi-tech adhesive solutions for all bonding and assembly needs. In fact, more than two billion cards a year already use our films for module embedding, satisfying the increasing demand for secured data.Module embedding is the process of adding a smart chip, either memory or micro-controller, to a plastic card by milling a profile into the card and bonding the module in place. Our automated solution is able to produce many thousands of cards per day from our Technical Centre.

smart card production technology

Smart card modules

Smart Cards

Module 1: Smart Card Fundamentals

How Smart Cards are Made – Part 1: Smart Card Module Production

Writing our own data to a Skylanders NFC toy. Create your own data to write, up to 720 bytes, and save it. For example, this is similar text to the demo video, saved as nfctoys-sky.txt. .

smart card module assembly|Module 1: Smart Card Fundamentals